Magnetic Inertia Jet Engine

Zero-contact magnetic bearings, regenerative power recovery, and cryogenic thermal control unite to deliver a jet engine platform that scales from advanced UAVs to hypersonic aircraft with unrivaled efficiency.

Mach 3.2+

Supersonic envelope via MI-SonicX 3300 configuration.

12,000 lbf

Magnetically suspended thrust capability without lubricant drag.

Multi-sector

Optimised for defense, commercial aviation, and autonomous UAVs.

Integrated propulsion intelligence

- Active magnetic suspension ensures frictionless spin at extreme RPM.

- Cryogenic loop maintains superconducting magnet integrity.

- Regenerative conversion feeds battery reserves for onboard systems.

- Adaptive control suite balances thrust, stability, and energy draw.

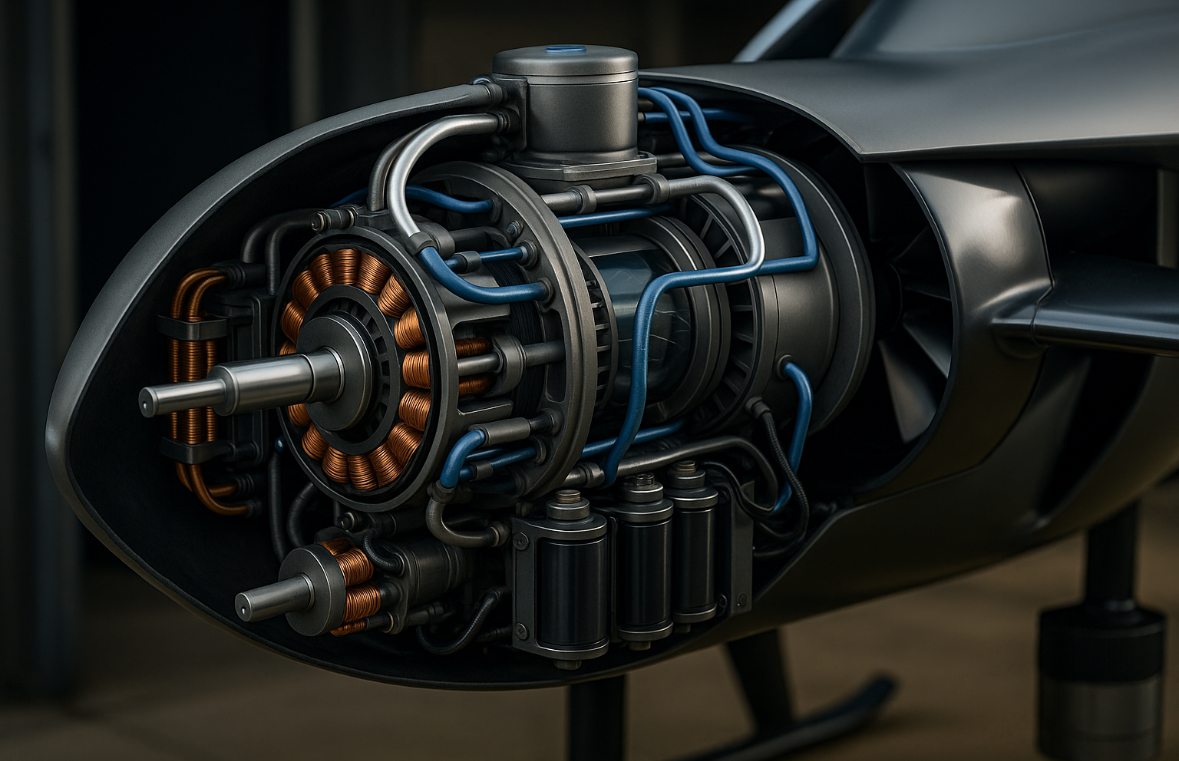

Field-ready drone integration visuals.

Mission photography highlights how the Magnetic Inertia Jet Engine adapts from compact UAV testbeds to long-endurance reconnaissance drones.

From rotor core to power electronics, every element is engineered for sustained precision.

The Magnetic Inertia Jet Engine blends aerospace-grade composites, superconducting fields, and digital control for unmatched performance in compact and full-scale propulsion programs.

Propulsion stack

- Magnetic main shaft isolates vibration and mechanical wear.

- Composite turbine stages sustain supersonic airflow dynamics.

- Embedded control unit orchestrates bearings, thrust, and diagnostics.

Energy & thermal systems

- Cryogenic cooling stabilises superconductors and prevents heat creep.

- Integrated storage banks buffer regenerative output for avionics.

- Fire suppression and redundant sensors safeguard mission uptime.

Deployment readiness

- Modular platform scales from UAV propulsion pods to crewed aircraft.

- Manufacturing roadmap aligns with aerospace-grade tolerances.

- Investment-backed partnerships accelerate certification pathways.

Precision options tailored for drone fleets, commercial trainers, and hypersonic defense.

| Model | Application | Top speed | Thrust class | Estimated weight | Target market cost |

|---|---|---|---|---|---|

| MI-MiniJet 200 | Drone/UAV | Mach 0.8 (980 km/h) | 150–300 lbf | 48 kg | $180,000–$280,000 |

| MI-Hybrid 800 | Commercial/Trainer Jet | Mach 1.8 (2,200 km/h) | 2,000–4,000 lbf | 460 kg | $1.2M–$2.0M |

| MI-SonicX 3300 | Military/Supersonic | Mach 3.2+ (3,900 km/h) | 8,000–12,000 lbf | 940 kg | $4.8M–$7.2M |

Core components underpinning the Magnetic Inertia propulsion assembly.

| Component | Unit cost (USD) | Quantity | Total cost (USD) |

|---|---|---|---|

| Main Shaft | $10,000 | 1 | $10,000 |

| Magnetic Bearings | $5,000 | 2 | $10,000 |

| Electromagnets | $500 | 4 | $2,000 |

| Superconducting Magnets | $2,500 | 4 | $10,000 |

| Turbine/Compressor Blades | $400–$600 | 20–30 | $8,000–$12,000 |

| Rotor Housing | $8,000 | 1 | $8,000 |

| Control Unit | $500 | 1 | $500 |

| Power Supply System | $250 | 1 | $250 |

| Energy Storage | $1,500 | 1 | $1,500 |

| Cryogenic Cooling System | $15,000 | 1 | $15,000 |

| Sensors | $50 | 6 | $300 |

| Fire Suppression | $2,000 | 1 | $2,000 |

Capital roadmap for prototyping, certification, and full-rate production.

$100k – $500k

High-grade alloys, superconductors, composites, and control electronics.

$250k – $500k

Precision fabrication for magnetic housings and turbine geometry.

$150k – $300k

Skilled integration teams for cryogenic, electrical, and propulsion systems.

$100k – $200k

Dyno, vibration, and flight simulations to qualify performance envelopes.

$500k – $2M

Continuous upgrades to superconducting materials and AI control loops.

$210k – $550k

Custom fixtures, certification tooling, and secure global distribution.

Total program outlook

$1.4M – $4.0M per full-scale engine inclusive of manufacturing and validation, with a $1.8M – $5.2M suggested market price covering service and performance guarantees.

Partner with Ioncore to redefine clean propulsion economics.

Capital profile

- Pre-Series A round targeting strategic aerospace and defense partners.

- Valuation range positioned between $30M – $45M.

- Minimum entry commitment of $500,000.

- Projected 5x ROI within five years through contracted programs.

Strategic exits

- Intellectual property licensing for established aerospace OEMs.

- Co-development agreements with global defense contractors.

- Embedded propulsion modules for autonomous and hybrid aircraft.

- Ioncore service alliances sustaining lifetime engine support.